♻️ Metal Scrap Conveyor System for CNC & Industrial Workshops

In CNC machining, turning, milling, stamping, and cutting operations, a large volume of metal scrap—such as chips, shavings, swarf, and fragments—is generated daily. Manual handling is labor-intensive, unsafe, and unhygienic.

A metal scrap conveyor system is the ideal automation solution to streamline the collection and transport of metal waste, helping reduce labor costs and enhance production efficiency.

🔧 Main Functions

-

Collect machining scraps (turning chips, milling swarf, cutting debris, metal fragments) directly from machines

-

Transport scrap to collection bins, crushers, or centralized storage

-

Enable continuous, automated scrap removal without interrupting operations

-

Minimize labor accidents caused by sharp metal waste

⚙️ Reference Technical Specifications

-

Frame material: Heavy-duty steel or stainless steel 304

-

Conveyor types: Hinge belt, chain conveyor, or scraper type

-

Motor: Integrated geared motor, 0.75 – 2.2kW depending on load

-

Optional features: Full-bin sensor, scrap collection hopper, integrated oil filtration system

-

Design options: Inclined, Z-type, or recessed floor-mounted structures

🏭 Common Applications

-

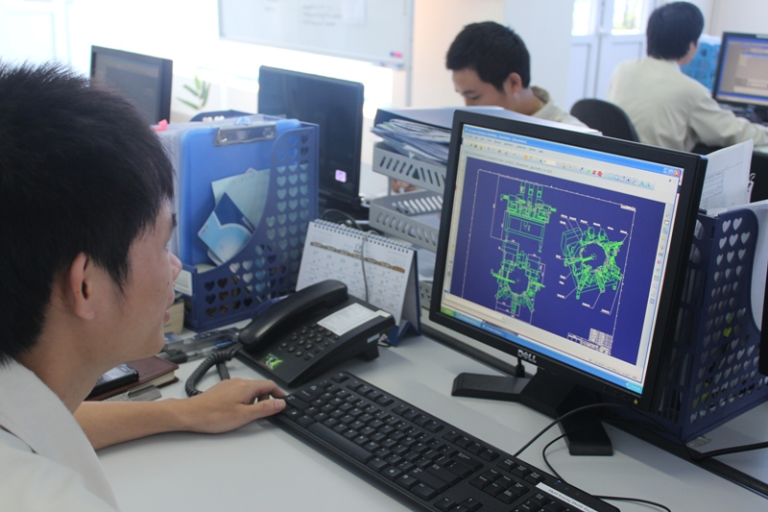

CNC turning and milling workshops

-

Sheet metal stamping and cutting lines

-

Aluminum or plastic injection molding machines

-

Precision engineering and mold-making factories

-

Automotive and motorcycle parts manufacturing plants

✅ Key Benefits

-

Improve productivity and reduce manual labor

-

Keep the workshop clean and support easier machine maintenance

-

Enhance safety by reducing slip and injury risks from sharp scraps

-

Easy integration with chip crushers, oil separators, or briquetting systems

-

Contribute to a cleaner and more sustainable production environment