During mechanical processing and wood manufacturing, operations such as turning, milling, drilling, and sawing generate large amounts of chips, wood dust, and metal shavings. Manual handling of these wastes not only requires significant labor but also disrupts production flow.

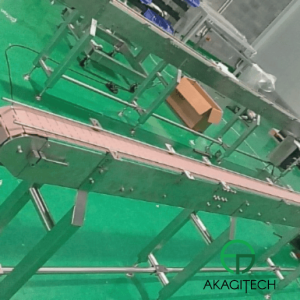

Akagitech provides specialized conveyor systems optimized for each processing type and the specific characteristics of chips and materials. Depending on the application, the system can utilize:

Hinge Type Conveyor

Screw Conveyor

Belt Conveyor

Magnetic Conveyor

Slat Conveyor

✅ Customized for various chip types: short or long, twisted or fine, metal or wood

✅ Modular assembly for flexible length extension and layout adjustment

✅ Direct connection to CNC machines, saws, drills, and lathes

✅ Automatic chip discharge into collection bins

✅ Minimizes dust and debris in workshops, improving working conditions

✅ Available in Z, L, or straight designs to suit installation site layouts

🛠️ CNC turning, milling, drilling workshops

🪚 Industrial wood processing plants

⚙️ Machine parts manufacturing facilities

🏗️ Construction machinery factories

🔩 Mold making and precision part machining

🪓 Automated sawing workshops

Conveyor length: from 500 mm to 10,000 mm

Adjustable speed: 1 m/min to 20 m/min

Drive motor: 0.1 kW to 2.2 kW with frequency inverter integration

Customizable width, inclination, and chip discharge height

Optional integration of sensors, emergency switches, cooling systems, and oil filters

Conveyor frame: SS400 steel with powder coating or SUS 304 stainless steel

Hinges, screws, belts: wear-resistant steel, oil-resistant PU, technical rubber

Safety features: side guards, warning sensors

Mounted on wheels or fixed legs

For each specific requirement, Akagitech conducts on-site surveys and creates CAD simulations prior to production to:

Ensure compatibility with existing equipment

Optimize cost and space usage

Minimize operational disruption

Meet fast deployment schedules

Free consultation and on-site survey

Detailed 2D/3D drawings

Turnkey delivery, installation, and commissioning

Technical warranty and periodic maintenance

24/7 after-sales support and readily available spare parts