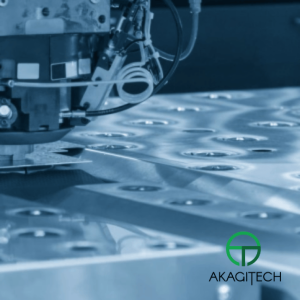

In the era of modern industrial manufacturing, laser cutting machines are a widely used material processing technology, applied extensively across industries such as mechanical engineering, automotive, metal furniture, electrical cabinets, metal signage, and more. However, during operation, laser machines generate significant amounts of metal dust, debris, and waste that must be promptly and effectively handled to ensure hygiene, safety, and productivity in factories.

Akagitech’s laser machine waste handling conveyor system is the ideal solution to automatically collect scrap material directly from the machine and transport it out to a designated disposal area, ensuring a clean, closed-loop, and efficient production process.

Direct connection to the laser machine:

The conveyor is installed directly under the laser cutting chamber to immediately collect falling debris. The design is integrated, discreet, and safe.

Z-shaped design optimizes space:

The Z-structure elevates waste above floor level, allowing direct discharge into waste bins or collection vehicles without occupying extra horizontal space. Perfect for workshops with limited floor area.

Optional conveyor types:

Hinge belt conveyor: Suitable for large debris and sharp metal fragments.

Magnetic chip conveyor: Designed for small ferromagnetic materials, fine metal dust.

Automated control integration:

Equipped with load sensors, frequency inverters for speed adjustment, and either a centralized control cabinet or connection to the factory’s PLC system.

Custom design tailored to machine location, waste type, volume, and workshop layout.

Manufactured from SUS 304 stainless steel or powder-coated steel—wear-resistant, heat-tolerant, and durable in dusty, hot environments.

Flexible load capacity: from a few kilograms up to tons of waste per day.

High safety standards: emergency stop switches, motor protection, enclosed housing to prevent chip scattering.

Easy maintenance: modular design for quick disassembly, cleaning, and parts replacement.

✅ Increased production efficiency: Continuous operation without machine stoppage for waste cleaning.

✅ Reduced labor costs: Eliminates manual scrap collection work.

✅ Enhanced factory safety: Reduces metal dust, lowers fire and slip hazards.

✅ Laser machine protection: Prevents waste buildup that causes overheating and precision loss.

✅ Optimized workshop space: Compact, intelligent design customized to actual layout.

Electrical cabinet manufacturing plants, machine housings, metal frames

Stainless steel, steel, iron, aluminum laser cutting workshops

Mechanical fabrication industry

Medical equipment and metal furniture sectors

Factories operating high-power fiber laser machines

🎯 On-site survey and free solution consultation

🎯 2D/3D design and spatial optimization simulation

🎯 Fabrication, installation, and on-site warranty service

🎯 Operation training and long-term technical support

🎯 Ready stock of spare parts with rapid 24-hour response