🚀 PVC/PU Anti-Static Conveyor – Model ATAB-F-200-6.0

Optimized Solution for Factory Automation

In today’s advanced manufacturing industries—especially electronics, food processing, pharmaceuticals, and precision engineering—anti-static conveyors are essential for ensuring product safety and optimizing production efficiency.

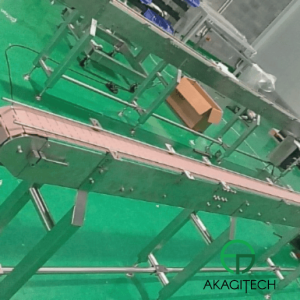

The ATAB-F-200-6.0 conveyor by Akagitech is a premium-grade modular conveyor system, designed with an aluminum frame and integrated anti-static belt materials. It offers exceptional versatility and is ideal for integration into modern automated production lines.

🔧 Key Specifications

Model: ATAB-F-200-6.0

ATAB: Aluminum-profile belt conveyor

Type: Straight (F), L-shape, or Z-shape (customizable)

Belt Width: 200 mm (adjustable from 200 mm to 2000 mm)

Conveyor Length: 6,000 mm (options from 500 mm to 20,000 mm)

Belt Material: PVC or PU, anti-static, 1–5 mm thickness

Max Speed: Up to 30 m/min (adjustable via inverter)

Frame: Aluminum profile with aluminum/304 stainless steel joints

Rollers: Aluminum or chrome-coated steel

Motor: From 15W to 2.2kW

Voltage: Customizable (220V, 380V, 200V, 100V – 50/60Hz)

✅ Key Features

🔹 Excellent Anti-Static Performance

Protects electronic components and operators in sensitive environments by preventing electrostatic discharge and interference.

🔹 Flexible Layout Options (F, L, Z)

Maximizes space utilization and allows seamless integration with existing production lines.

🔹 Adjustable Speed Control

Speed can be changed easily via manual switch or inverter, matching the workflow of each production phase.

🔹 Premium Materials – High Durability

Aluminum frame and stainless steel components resist corrosion, heat, and oil—ensuring long-term stable operation.

🔹 Full Customization Available

Dimensions, height, belt type, motor capacity, and additional accessories such as side guards, guide rails, or mobile wheels can all be tailored to specific needs.

🏭 Common Applications

Electronics industry: PCB assembly, electronics inspection, testing

Food & Pharma: Cleanroom product transport and packaging lines

Automotive & EV: Sub-assembly transport of components and mechanical parts

Garment & Footwear: Material feeding and finished product handling

Plastics & Rubber: Transport of high-temperature parts with stable belt performance

Stamping & Metalwork: Handles heavy vibration, oil exposure, and impact loads reliably

⚙️ Advanced Customization Options

Adjustable Height & Angle:

Support legs can be fitted with caster wheels or leveling bolts.

Belt Options:

Available with guide ribs, scrapers, cleats, or wave edges for anti-slip and product control.

Smart Control Systems:

ON/OFF switches, inverter speed control, timers, emergency stops, material sensors, pneumatic pistons, etc.

Brand Customization:

Frame coating and color can match customer branding and factory design.

Load Capacity Range:

Engineered to transport anything from light electronic parts to heavy molds or large mechanical components.

🎯 Why Choose Akagitech Conveyors?

Expert design team with over 10 years of industry experience

Assembled in Vietnam – fast delivery, easy local maintenance

100% Custom-built to match your real production line

On-site consultation, technical drawing support, and automation-ready solutions

📞 Need a custom conveyor system for your production line?

Contact Akagitech today – we’re ready to assist with consultation, on-site survey, and tailor-made solutions at the most reasonable cost for your factory.