⚙️ Main Components

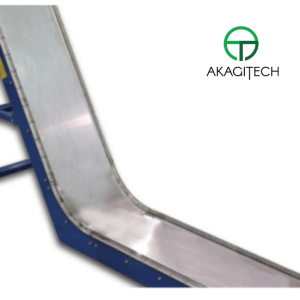

Frame: Made from SS400 steel or stainless steel 304, powder-coated for anti-corrosion

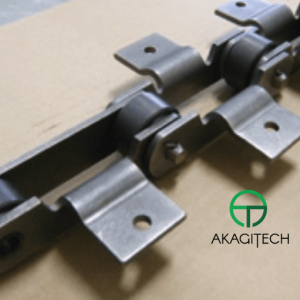

Conveyor chain: Double chain or heavy-duty plate chain for strong transmission

Scraper blades: Made of sheet steel or galvanized steel, with teeth for effective material scraping

Drive motor: Options from 0.75kW to 3.7kW, equipped with reduction gearbox

Chain tensioner: Manual or automatic chain tensioning system

Electrical control: Integrated PLC control cabinet with ON/OFF switch, fault indicators, and reverse operation function

🛠️ Key Features

🔩 High load capacity – suitable for heavy materials such as steel chips, stainless shavings, aluminum swarf

🔄 Stable transmission – reduces vibration and ensures smooth operation

🛡️ Resistant to oil, dust, and high temperatures

🔧 Customizable: length, width, transport speed, discharge height, and orientation tailored to your requirements

🧰 Typical Applications

♻️ Transporting metal chips from CNC machines to centrifuges or chip bins

🔩 Used in scrap collection and processing lines

🔄 Works in sync with chip crushers, compactors, and oil filtration systems

🔧 Widely used in mechanical workshops, mold manufacturing, metal processing, and automotive plants

📐 Custom Technical Specifications

Conveyor length: from 1.5m to 20m

Scraper width: from 300mm to 1000mm

Discharge height: available in inclined or L-shape configurations

Chain type: double or plate chain depending on load

Conveyor speed: adjustable on request (optional frequency inverter)

Motor type: 220V, 380V, or explosion-proof as required

Paint finish: standard industrial paint or customized to customer brand identity

📌 Why Choose Akagitech?

Designed according to actual layout and on-site installation conditions

Manufactured to meet industrial safety standards

Full-package support including maintenance and technical consultation

Flexible solutions for custom projects across various industries