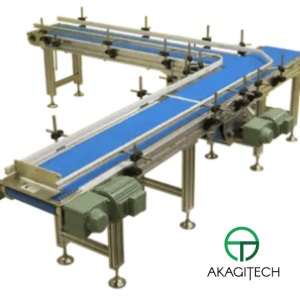

🥗 Stainless Steel 304 Food Conveyor – Model ATVB-TP-01-200-1.5

Compact, Precise & Hygienic Conveyor for Cleanroom & Food Applications

The ATVB-TP-01-200-1.5 food-grade conveyor is specially engineered for compact production lines in food, pharmaceutical, and cleanroom environments where hygiene, accuracy, and efficient use of space are critical. Featuring a durable stainless steel frame and a mid-mounted motor, this compact conveyor is ideal for precise, lightweight material handling.

📐 Key Technical Specifications

Model: ATVB-TP-01-200-1.5

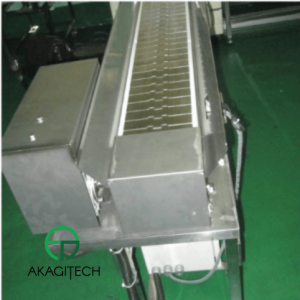

Conveyor Type: Food-grade PVC/PU belt

Belt Width: 200mm

Total Length: 1500mm

Roller Diameter: Ø27mm – ideal for small/lightweight items with high accuracy

Frame Material: Stainless Steel 304 – corrosion-resistant, easy to clean

Frame Style: Standard straight configuration

Motor Position: Center-mounted for stability and space efficiency

Motor Power: 15W – 2.2KW

Speed: Up to 30m/min – adjustable as required

⚙️ Smart Control System

Basic Speed Control: ON/OFF switch with integrated motor controller

Advanced Option: Inverter (VFD) for precise speed regulation

Automation Ready: Optional timers, emergency stop switches, object sensors, pneumatic pistons, etc.

🌟 Product Highlights

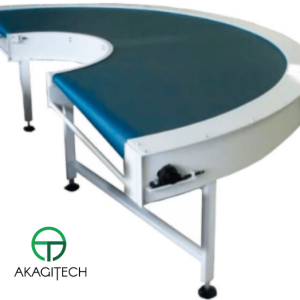

Compact & Space-Saving: Ideal for narrow production areas

Hygienic Design: Inox 304 and food-grade belts for easy cleaning

Precision Handling: Suited for lightweight, high-accuracy applications

Quiet & Energy-Efficient: Low-noise, stable operation

Flexible Dimensions:

Belt Width: 50mm – 1000mm

Length: 500mm – 5000mm

Speed Control: Easily adjustable for different processing stages

Safety Features: Optional side guards, cleats, guide ribs to prevent product slippage

Custom Belt Colors: White, blue, gray, or branded colors

Voltage Compatibility: 100V – 380V (50Hz / 60Hz)

🏭 Common Applications

Food Industry: Transporting cakes, fruits, seafood, and light raw materials

Pharmaceuticals: Tablet packaging and sorting lines

Cosmetics: Handling small bottles, tubes, or cosmetic containers

Cleanroom Environments: Designed to meet GMP/HACCP standards

Sorting & Separation: Ideal for use in confined production zones or tight conveyor segments

🧩 Optional Technical Customizations

Adjustable Frame: Height & tilt angle customizable; fixed legs or caster wheels

Speed Options: Fixed or variable speed via inverter or toggle switch

Integrated Electronics: Object sensors, emergency stops, timers, push ejectors

Belt Enhancements: Cleats, guide ribs, sidewalls for better control

Safety Guards: Prevent product from slipping or falling

Motor Placement: Customizable to bottom or side-mounted upon request

Power Specs: Voltage and motor specs configurable for your local standard

Load Capacity: Tailored to suit light or medium-weight products

Belt Color: White, blue, gray, or according to your brand identity

🎯 Why Choose Us?

Free 2D/3D Design Consultation: Tailored to your production layout

Custom Manufacturing: No mass production – made to your specs

12-Month Warranty & Lifetime Tech Support

Precision Craftsmanship: Each unit quality-checked and tested

Nationwide Delivery & On-Site Setup Available (Vietnam)

📞 Reach out today to get expert consultation and a tailored conveyor system for your clean production needs.